In 1944, more than 44,000 blacksmiths professionally pounded on anvils in the U.S, steely muscles rippling as they hefted hammers, forging iron hardware, shoeing the occasional horse, their flint-grey eyes reading the yellow and red heat in the wrought iron buried in burning charcoal. By the time the Bureau of Labor Statistics (BLS) counted blacksmiths in this country for the last time in 1981, only 11,000 blacksmiths plied their craft.

Automation had quenched the fires of a once-proud industry. Nobody wrote scholarly articles about the sad disappearance of village blacksmiths, or turret-lathe operators, or locomotive firemen. Machines—advanced manufacturing of its day—replaced muscle in all those occupations, and those jobs have all but disappeared. Advanced manufacturing hastens the demise of some jobs even as it gives rise to amazing new careers. Those with advanced education always profit from keeping an eye to the future.

What is Advanced Manufacturing?

A May, 2014 survey by Advanced Manufacturing Media (AMM) breaks down the technologies that distinguish Advanced Manufacturing companies:

- Advanced manufacturing equipment

- Advanced software

- Advanced sensing, measurement, and process control

- Industrial robotics

- Information technologies and digital manufacturing

- Sustainable manufacturing

- Cyber security

- Additive manufacturing

- Advanced materials

- Advanced forming

- Flexible electronics

- Nano-manufacturing

- Bio-manufacturing and bioinformatics

This is a huge menu, with some self-described categories that could work in any era—remember the stamping mill that replaced the blacksmith was advanced manufacturing equipment in its day—but some are very much only of the 21st century. Nano-manufacturing and bioinformatics are threshold industries, waiting for the right talent to explode onto the scene.

How Does Advanced Manufacturing Improve Our Lives?

From the boardroom windows, advanced manufacturing techniques bulge the bottom line:

- Lowered production costs—More than 30 percent of respondents to AMM’s survey pointed to this overall improvement

- Improved production speed

- Improved product quality and reliability—37 percent reported this benefit

From the engineers’ and designers’ viewpoints at their CAD stations, 30 percent of those AMM surveyed said advanced manufacturing led to improved product complexity and performance—each iteration of a product includes more complicated improvements, and more of them. Want proof? Check out a ten-year-old cell phone.

American Made

Those proliferating pundits who wistfully cry over the fall of Detroit’s Big Three or the disappearance of Pennsylvania’s belching steel furnaces make one mistake: they think massive plants are the future.

A subtle revolution in advanced manufacturing is transforming American industry. Advanced manufacturing techniques rewrite methods of developing, producing, shipping and selling products.

Companies need not encompass acres of real estate with hundred-foot smokestacks to produce competitive, sustainable products the world wants. Small companies, with nimble response times, adapt to customer needs and push advanced manufacturing methods ever-forward.

Customer Catering

Higher quality products, lower costs, reduced environmental impact, and streamlined operations are all hallmarks of advanced manufacturing. Customers for these competitive products are in the AMM survey’s top five trades:

- Metal fabrication—There are your modern-day blacksmiths

- Aerospace and defense—No operating environment is more complicated or challenging than outer space

- Automobile and truck manufacturing—Detroit is doing fine, thank you, and vehicles are built all over the country

- Machinery manufacturing

- Surgical and medical instruments

A student of mechatronics may be surprised that those top industries did not include electrical, computer or electronics equipment. Those industries—eighth and 11th on the AMM list—are obvious landing places for talented male and female electronics engineers, but they are not the only career paths.

No More Blacksmiths

The BLS adds and removes job descriptions constantly, which is why blacksmiths are no longer counted. Mechatronics has not made it into BLS’s statistics yet (no doubt it will), so we have to look at the job outlook for “electro-mechanical technicians,” which by now sounds as antiquated as “factory lector” (someone who read the newspaper out loud to illiterate factory workers).

The BLS adds and removes job descriptions constantly, which is why blacksmiths are no longer counted. Mechatronics has not made it into BLS’s statistics yet (no doubt it will), so we have to look at the job outlook for “electro-mechanical technicians,” which by now sounds as antiquated as “factory lector” (someone who read the newspaper out loud to illiterate factory workers).

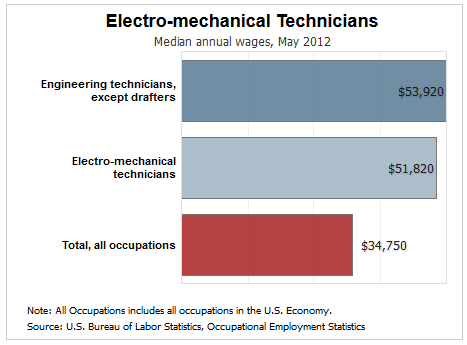

BLS points to the median annual income of electro-mechanical technicians earning $51,820 annually, with the top 10 percent making more than $76,590 annually and the lowest 10 percent making less than $33,360, as of May, 2012.

The Challenge

Just as telling as the glowing numbers in AMM’s report and the BLS are the dying embers of companies that are not making improvements in advanced manufacturing methods. While more than half who responded to AMM said their companies could not afford (which can also mean "they did not fund") advanced manufacturing improvements, 32 percent said their employees lacked the technical skills to implement advanced manufacturing improvements. That just may be where you come in.

Learning how to solder this morning. I'm in love. #Nerd #soldering @ ECPI College of Technology http://t.co/qoUd4NS4J8

— Ash (@OatzTheGreat) December 12, 2014

Earn a Degree in Advanced Manufacturing

Where are the employees with the skills needed to keep fueling the industry improvements in advanced manufacturing? They are sitting in their homes, reading this, wondering what to do for a career. You could be earning a Bachelor of Science Degree in Electronics Engineering Technology with a concentration in Mechatronics. In around two and a half years, you could emerge with all the skills needed to be part of tomorrow’s American industry. Contact ECPI University today to learn about our mechatronics degree program and find out why so many students come to ECPI. It could be the Best Decision You Ever Make!

DISCLAIMER – ECPI University makes no claim, warranty or guarantee as to actual employability or earning potential to current, past or future students or graduates of any educational program we offer. The ECPI University website is published for informational purposes only. Every effort is made to ensure the accuracy of information contained on the ECPI.edu domain; however, no warranty of accuracy is made. No contractual rights, either expressed or implied, are created by its content.

For more information about ECPI University or any of our programs click here: http://www.ecpi.edu/ or http://ow.ly/Ca1ya.